Elektron® 21 Direct Chill Strand Cast

Elektron® 21 Direct Chill Strand Cast is the a high-performance magnesium alloy specifically developed for demanding aerospace applications, designed to provide superior mechanical properties and improved corrosion resistance with an operating temperature up to 200˚C.

The versatility of this alloy makes it of interest to a wide range of designers dealing with aerospace, automotive, military and electronic applications.

Castings in Elektron®® 21 is the material of choice for transmission housings for commercial and military helicopters. It is also a perfect fit for aircraft engine parts such as gearbox housings and covers, electronics casings.

AMS: 4431

UNS: M12310

ASTM: B80

ISO 16220 MC65410

Zinc: 0.2–0.5%

Neodymium: 2.6–3.1%

Gadolinium: 1.0–1.7%

Zirconium: 0.4–1%

Magnesium: Balance

Our material is selected internally using ultrasonic testing according to the AMS 2154A class AA.

100% of our materials go through a radiography inspection in a NADCAP facility to meet the AMS 2175A Grade B.

Specific gravity: 1.82

Coefficient of thermal expansion: 26.3 x 10-6K-1

Thermal conductivity at 50 ˚C: 80 Wm-1K-1

Specific heat: 1086 Jkg-1K-1

Electrical resistivity: 94.6 nΩm

Modulus of elasticity: 44.8 x 10³ MPa

Poisson’s ratio: 0.27

Melting range: 545 ˚C–640 ˚C

Brinell hardness: 65–75

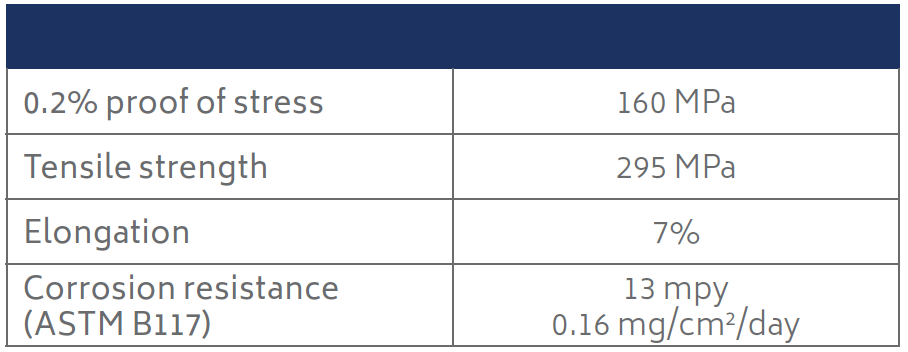

Minimum specification (A basis statistical):

0.2% proof stress: 145 MPa

Tensile strength: 248 MPa

Elongation: 3%

Corrosion resistance (ASTM B117): 40 mpy

0.51 mg/cm2/day

Rounds/Billets up to 225 mm diameter by 1,000 mm in length.

Rectangle/Slabs up to 250 mm by 700 mm by 1,000 mm in length.

Bigger sizes could be made upon special request.

Castings are given a T6 heat treatment to obtain optimum mechanical properties.

Elektron® 21 Direct Chill Strand Cast can be machined faster than any other metal and save precious time and reduce cost.

Please contact us for additional information on machining best practices for magnesium alloys.

Standard conversion coatings, anodising and Plasma Electrolytic Oxidation (PEO) systems can be applied as a pre-treatment before primer and paints.

Elektron® 21 shows superior fire resistance compared to traditional magnesium alloys. Elektron® 21 has demonstrated equivalent level of safety to Aluminium alloys (baseline) in aircraft passenger cabin occupancy.

It passes the following FAA/EASA Fire Tests:

- Oil Burner Flammability Test for Magnesium Alloy Seat Structure Chapter 25

Typical tensile properties at room temperature design data

Table 1.

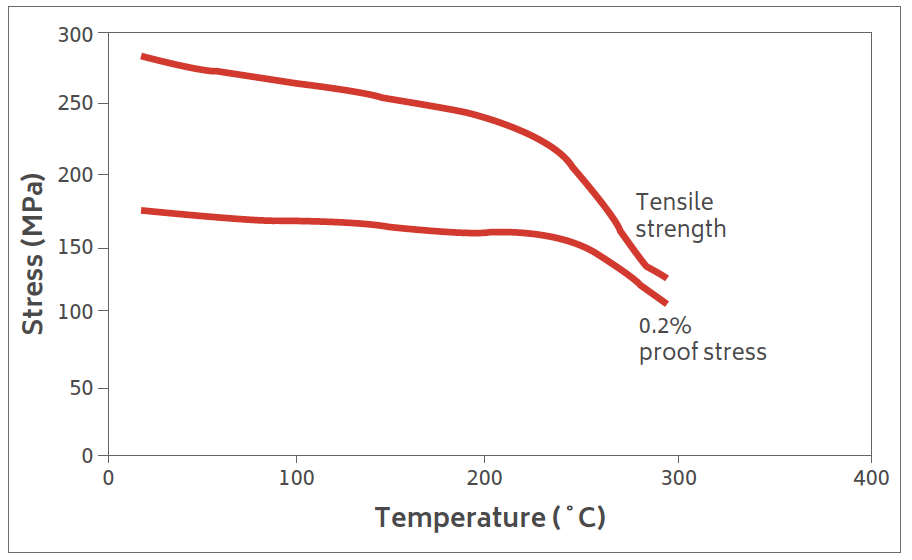

Elevated temperature mechanical properties(1)

Figure 1. Effect of temperature on tensile properties.

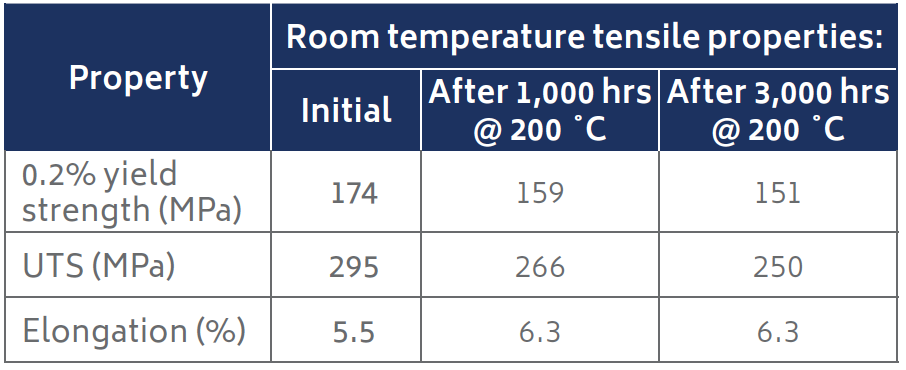

Table 2. Room temperature tensile properties after long term heat exposure – Minimum of 3 test bars at each test condition.

Figure 2. Fatigue curves for DC cast Elektron® 21, tested at room and elevated temperature at rotating frequencies 50 Hz and 150 Hz adjusted to a run out of 20 million cycles.