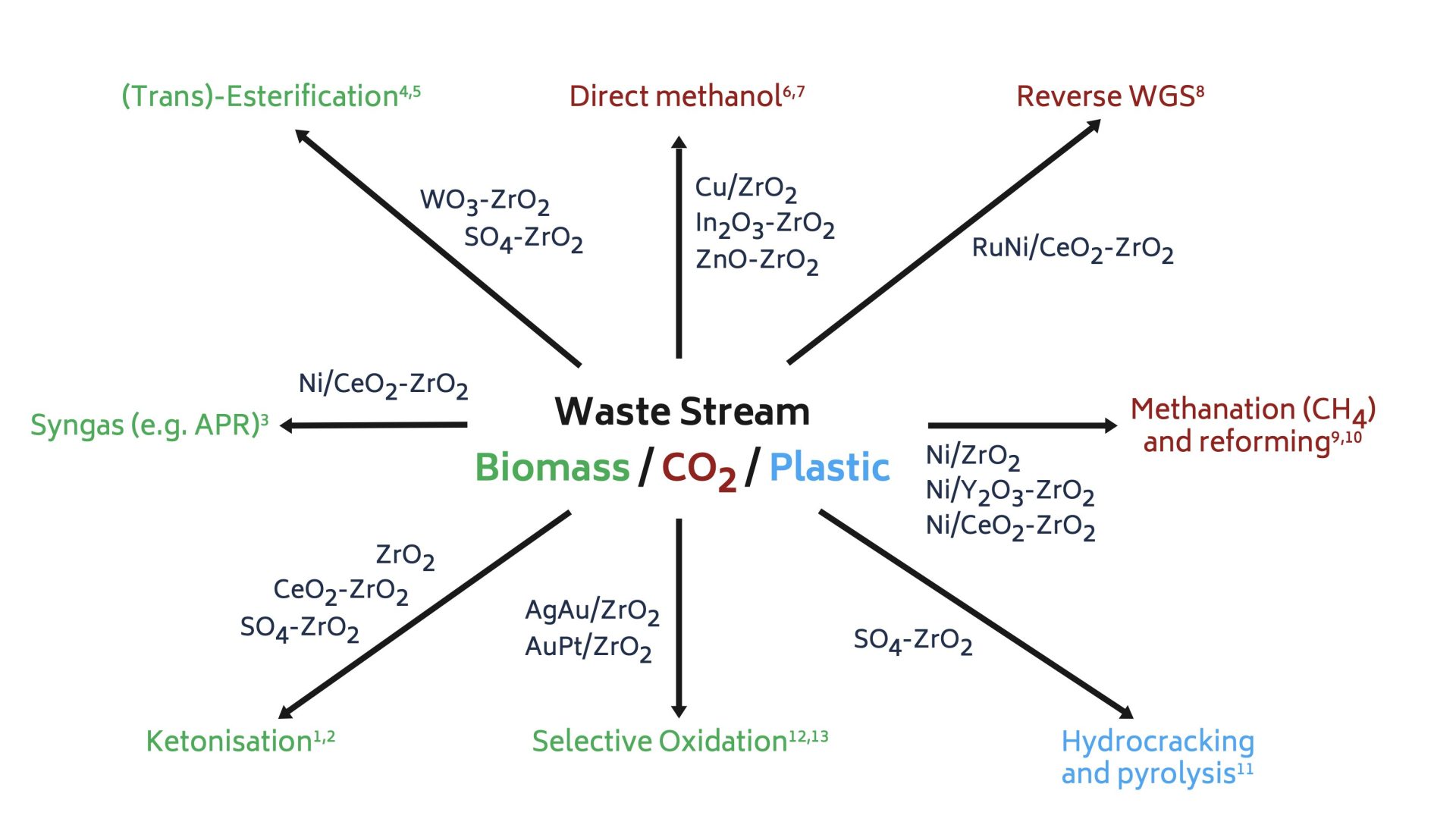

Zirconia-based materials for catalytic conversions

Luxfer MEL Technologies supplies both doped and undoped zirconium compounds (hydroxides and oxides) for use in a wide range of catalytic applications. Materials are solid powders, with tunable properties resulting from our proprietary manufacturing processes. These are carried out at multi-ton scale. LMT also supplies zirconium solutions that are frequently used as binders (or indeed a Zr-source) in catalyst forming.

Catalysts can be easily separated from the reaction media.

High activity / low temperature operation

Good interaction with supported metals, and properties can be modified by dopants.

Structure

They have developed (tunable) porosity and defined crystalline structure.

Stability

Particularly under hydrothermal (aqueous) conditions, ideal for ‘green’ processes.

Reusability

Catalysts can be used several times during reaction cycle.

Environmentally friendly

Zirconia-based materials do not release any halogen containing or other compounds which might corrode equipment, impact eco-system.

*Other dopants can potentially be worked with, e.g. transition metal oxides, other rare-earth oxides, SnO2, Nb2O5, PO4.

Multiple dopants/combinations are also manufactured on a regular basis.

Typically has involved isomerisation of alkanes in gasoline upgrading (super-acid).

However, zirconia-based supports have attracted a lot of interest for “green” processes, for example cellulose conversion14. Other examples are shown on the next page.

- Lilga, M. A. et al., Catalysis Today, 302, 2018, 80-86

- Huq, N. A., et al., PNAS, 118 (13), 2021, e2023008118

- Coronado, I., et al., Applied Catalysis A : General, 567, 2018, 112-121

- Dos Santos, V. C., et al., Applied Catalysis B : Environmental, 162, 2015, 75-84

- Sani, Y. M., et al., Applied Catalysis A : General, 470, 2014, 140-161

- Li, K, and Chen, J. G., ACS Catalysis, 9, 2019, 7840-7861

- Ye, R., et al., Nature Communications, 10, 2019, Article No. 5698

- Sache, E. L., et al., ACS Sustainable Chemistry & Engineering, 11, 2020, 4614-4622

- Frontera, P., et al., Catalysts, 7 (2), 2017, 59

- Fakeeha, A. H., et al., Journal of Saudi Chemical Society, 25, 2021, 101244

- Almustapha, M. N., et al., Journal of Analytical and Applied Pyrolysis, 125, 2017, 296-303

- Mounguengui-Diallo, M., et al., Applied Catalysis A : General, 551, 2018, 88-97

- Schade, O. R.. et al., Advanced Synthesis & Catalysis, 362, 2020, 5681-5696

1Nguyen, V. C., et al., Molecular Catalysis, 476, 2019, 110518