Elektron® 43 Extruded Products

Applications

Elektron® 43 is a light, high strength wrought magnesium alloy for use at temperatures up to 250˚C. Designs in Elektron® 43 can be 20% to 30% lighter than a corresponding aluminium design. Elektron® 43 is available as rolled plate, forging feedstock and extruded bar, section and profile. Elektron® 43 is an optimised wrought evolution of the original casting alloy, Elektron® WE43.

The properties of Elektron® 43 mean it is well suited for use as feedstock material from which to machine high performance components, especially those associated with elevated temperature performance.

Elektron® 43 has undergone extensive flammability testing by the Federal Aviation Administration (FAA).The FAA have shown that the use of Elektron® 43 in aircraft seat frames does not reduce the level of safety of the aircraft when compared to heavier aluminium seat components.

- UNS M18434

- ASTM WE43C

- AMS 4485 – Extrusion

- ASTM B107 and B107M – Extrusion

- MMPDS-08 (and later versions) – Including full

A and B basis statistical analysis of properties for

bothextrusions and plate.

- Yttrium: 3.7 – 4.3%

- Rare earths: 2.3 – 3.5%

- Zirconium: 0.2% min

- Magnesium: Balance

Extruded Elektron® 43 develops its maximum strength in the artificially aged (T5) heat treated condition.

Specific gravity: 1.83

Coefficient of thermal expansion: 25.6 x 10-6K-1

Thermal conductivity: 57.6 Wm-1K-1

Specific heat: 993 Jkg-1K-1

Electrical resistivity: 148 nΩm

Modulus of elasticity: 44.1 GPa

Poisson’s ratio: 0.3

Melting range: 540 – 640˚C

Damping index: 0.09

Brinell hardness: 70 – 90

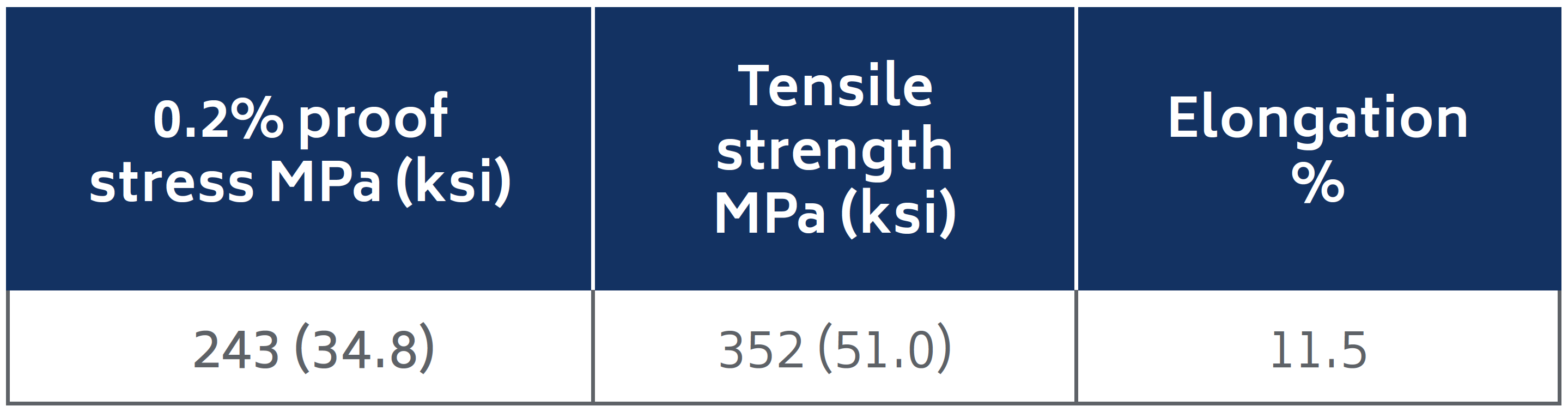

Longitudinal – Specification minima (A-basis statistical)

Extruded – T5

0.2% proof: 195 MPa (28.2 ksi)

Ultimate tensile strength: 303 MPa (43.9 ksi)

Elongation: 6%

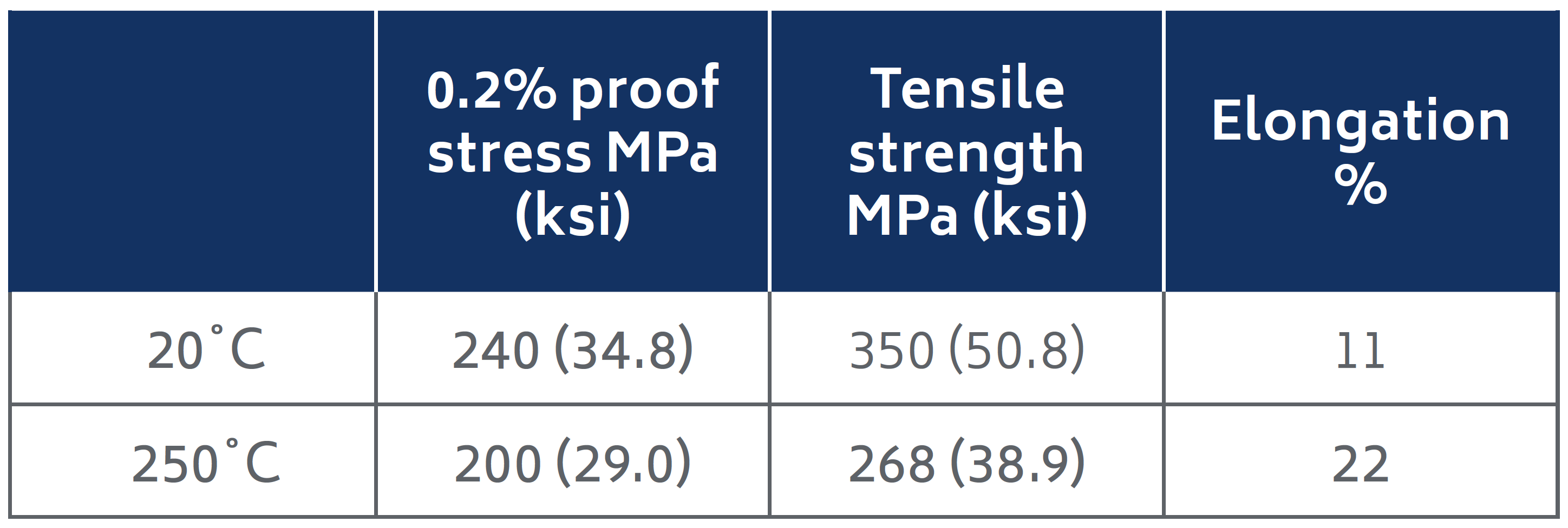

Ambient temperature mechanical properties

T5 properties for extruded Elektron® 43 are dependent upon extruded profile. Tensile strength values up to 300 MPa 0.2% PS (43.5 ksi); 375 MPa UTS (54.4 ksi); and elongation of 11% have been demonstrated.

Extruded bar – Longitudinal

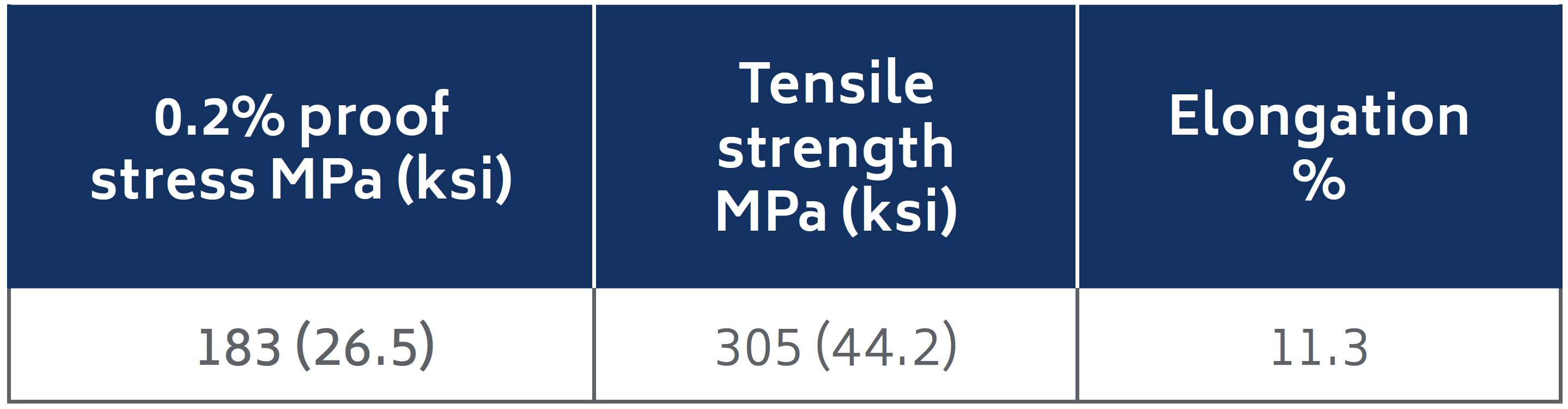

Extruded bar – Transverse

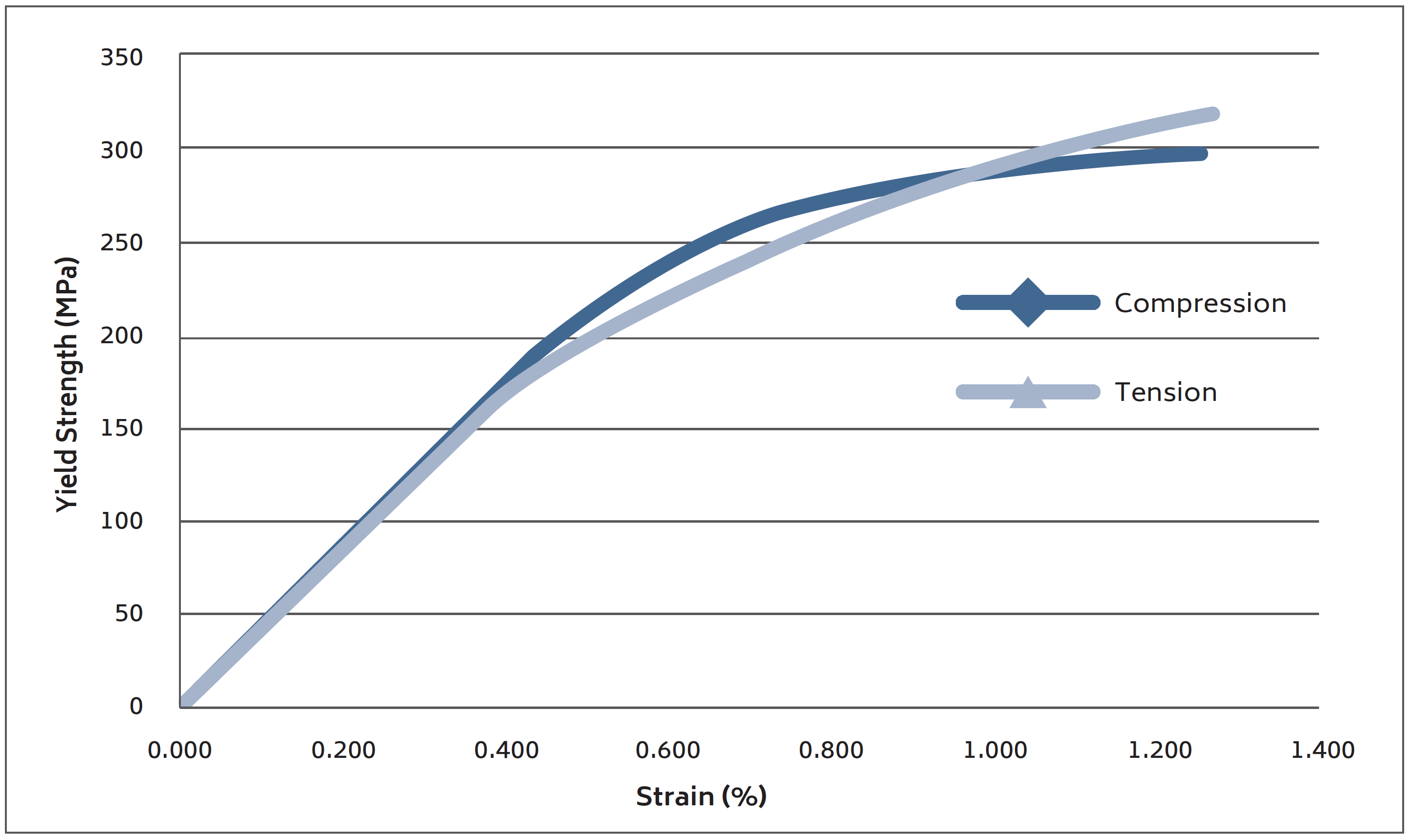

Asymmetry is when the tensile yield strength is greater than the compressive yield strength due to the twinning behaviour. Elektron® 43 has reduced asymmetry compared to other magnesium alloys.

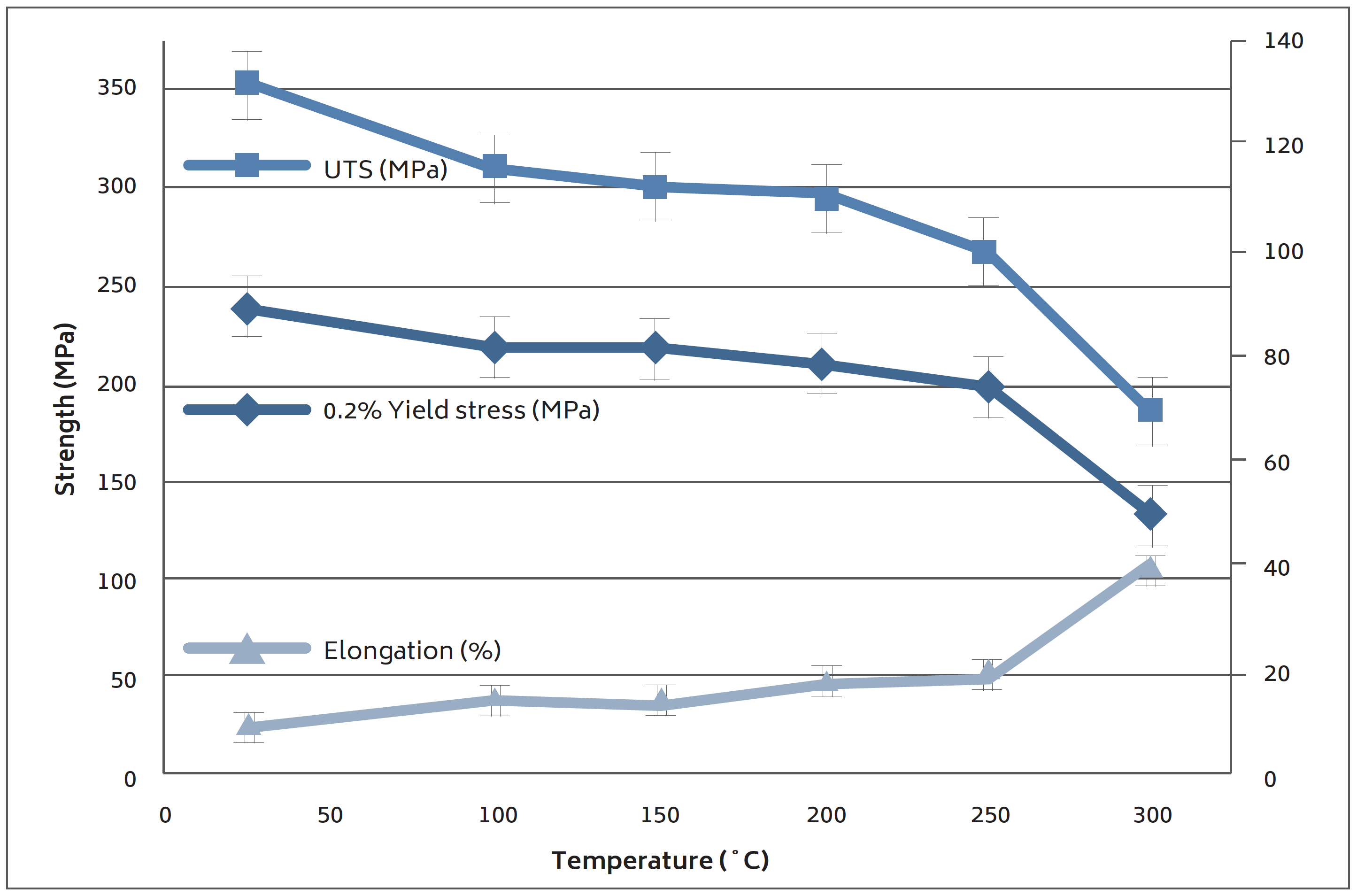

Elevated temperature properties

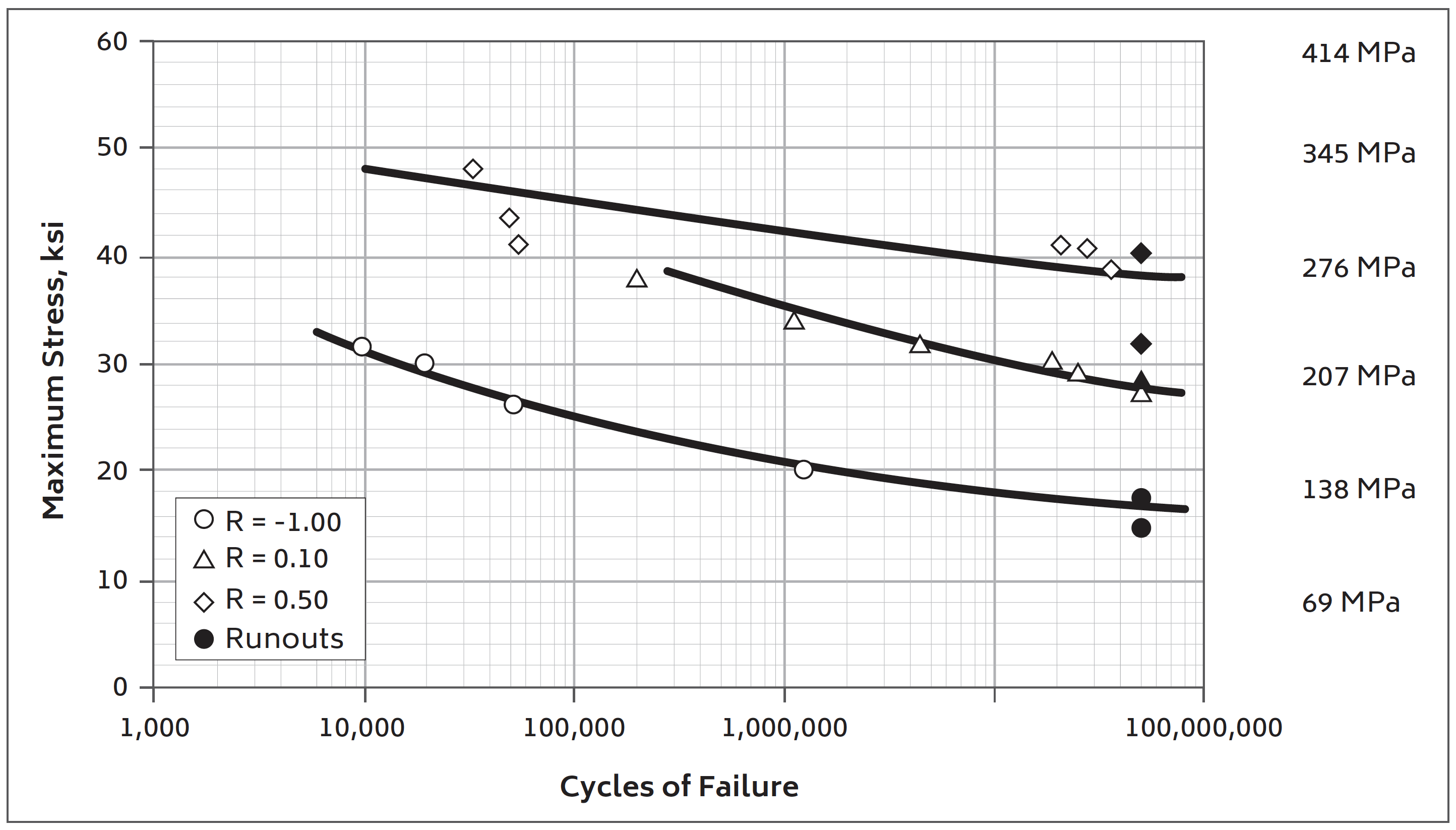

Extruded bar – Fatigue properties ASTM E466 axial fatigue

R=0.1 at 50 million cycles = 195 MPa

Other R ratios are shown in the graph below.

Plate

Elektron® 43 rolled plate is available and has specification AMS 4371. Please see Magnesium Elektron® Datasheet 492.

Forging

Elektron® 43 is a high strength alloy that responds well to forging – please see Magnesium Elektron® information sheet, available on the website, for the forging of Elektron® 43.

Machining

Elektron® 43, like all magnesium alloys, machines faster than any other metal.

Corrosion resistance

Corrosion rate < 30 mpy

Surface treatment

Elektron® 43 can be anodised with treatments including: Keronite®, Tagnite® and MagOxid®, amongst others.

Conversion coatings that are Hexavalent chromium free are also available. These include:

Alodine® 160/161, Surtec® 650, Metalast® TCP-HF,

Oxsilan® MG 0611, Gardobond® X4729, and

MagPass®, amongst others.

Like all magnesium alloys, Elektron® 43 can be painted or coated using conventional techniques following pre-treatment.