Elektron® Cast Billet

Direct chill cast billet is manufactured by Luxfer MEL Technologies as the starting material for other magnesium products, such as sheet, forgings and extrusions. However, it has been frequently found that the cast billet is suitable for machining into prototypes, thus avoiding expensive tooling, and in some cases for production where the size of the finished item is outside economic casting or extrusion dimension or minimum economic production.

Cast billet is supplied to the compositional requirements but not the mechanical properties of the British/ASTM Standard for the corresponding wrought or cast alloy. With conventional casting alloys, if the billets were to be heat treated it would be expected that the specification minimum properties would be obtained though, due to the casting technique employed, no guarantee could be given.

Inspection standards for cast billet will be by agreement. Ultrasonic inspection to AMS-STD-2154 Class A or Class AA is available upon request. Temporary corrosion preventative surface treatments can be applied by agreement.

Luxfer MEL Technologies supplies direct chill continuous cast machining stock for manufacture of parts which are larger than possible by conventional production methods. Stock is rectangular, with two opposing faces machined, and then sawn to ordered size. The alloy for machining stock is AZ31B per the chemical composition requirements of ASTM B90.

Maximum thickness: 330 mm

Maximum width: 1,115 mm

Maximum length: 2,080 mm

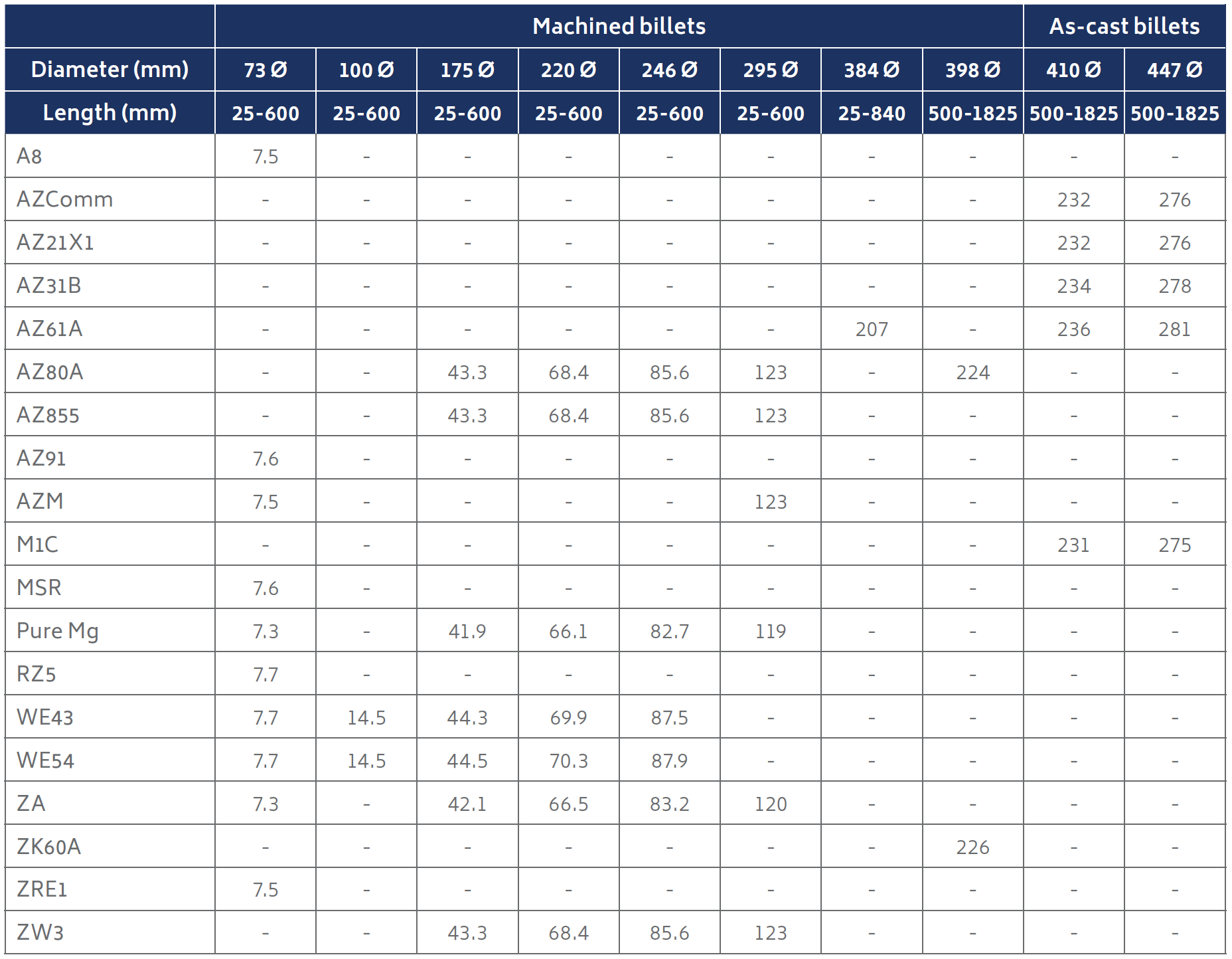

Nominal weight of available cast billet (kilograms per metre of billet length)

Alloy and size combinations without a listed weight may be available on inquiry.

Meet the Magnesium Forging Billet Team

Rick Tonge MBA

Product Line Manager

Europe, Middle East & Asia

Based in Manchester, UK, Rick supports our oilfield customers outside of North America. Partnering with our global customers, Rick enables his clients to design high performance products using Luxfer’s dissolving and non-dissolving material technology. Why not reach out to Rick today to discuss how Luxfer’s innovative material technology can work in your completion tools setup?

Request a call back

Error: Contact form not found.