US +1 908 782 5800 | UK & Rest of World +44 (0) 330 822 6000

Elektron® 43

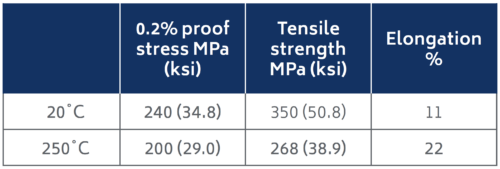

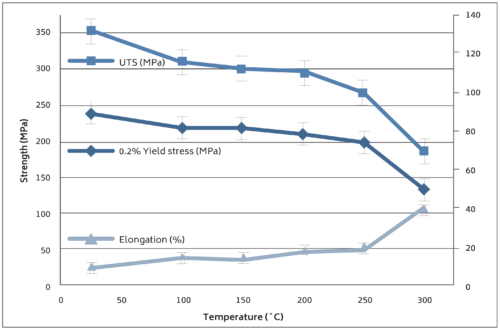

Elektron® 43 is a lightweight, high-strength wrought magnesium alloy for use at temperatures up to 250˚C.

The properties of of this alloy mean it is well suited for use as feedstock material used to machine high performance components, especially those associated with elevated temperature performance.

Designs in Elektron® 43 can be 20% to 30% lighter than a corresponding aluminium design.

This alloy is available as rolled plate, forging feedstock and extruded bar, section and profile.

Elektron® 43 is an optimised wrought evolution of the original casting alloy, Elektron® WE43.

Elektron® 43 has undergone extensive flammability testing by the Federal Aviation Administration (FAA). The FAA have shown that the use of Elektron® 43 in aircraft seat frames does not reduce the level of safety of the aircraft when compared to heavier aluminium seat components.

Product Information

Find out more about this product below.

Support and downloads

Make an enquiry

Please fill in this form to contact us for sales, support or general enquiries. Thank you.