US +1 908 782 5800 | UK & Rest of World +44 (0) 330 822 6000

Machining Magnesium

Magnesium is the lightest structural metal and offers exceptional machinability.

Key benefits include low cutting power requirements (~55% of aluminium), fast machining, excellent surface finish, well-broken chips, and reduced tool wear.

Machining Parameters

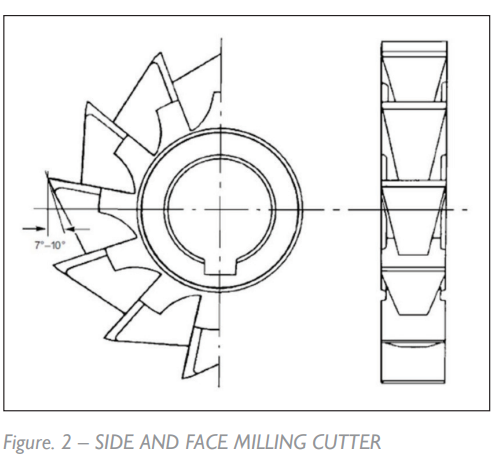

Magnesium’s specific cutting force is significantly lower than other metals, enabling high speeds (up to 3000 m/min in face milling) and large feed rates. Carbide and PCD tools are preferred for durability and superior finish. Tool geometry should feature sharp edges, large relief angles, and positive rake angles to minimize heat and chip buildup.

Dry Machining & Cooling

Magnesium is best machined dry due to its high thermal conductivity and free-cutting properties. However, cooling gases (argon, compressed air) or mineral oils may be used to manage temperature, especially in high-speed or deep-hole operations. Water-miscible coolants can be hazardous due to hydrogen generation unless specially formulated for magnesium.

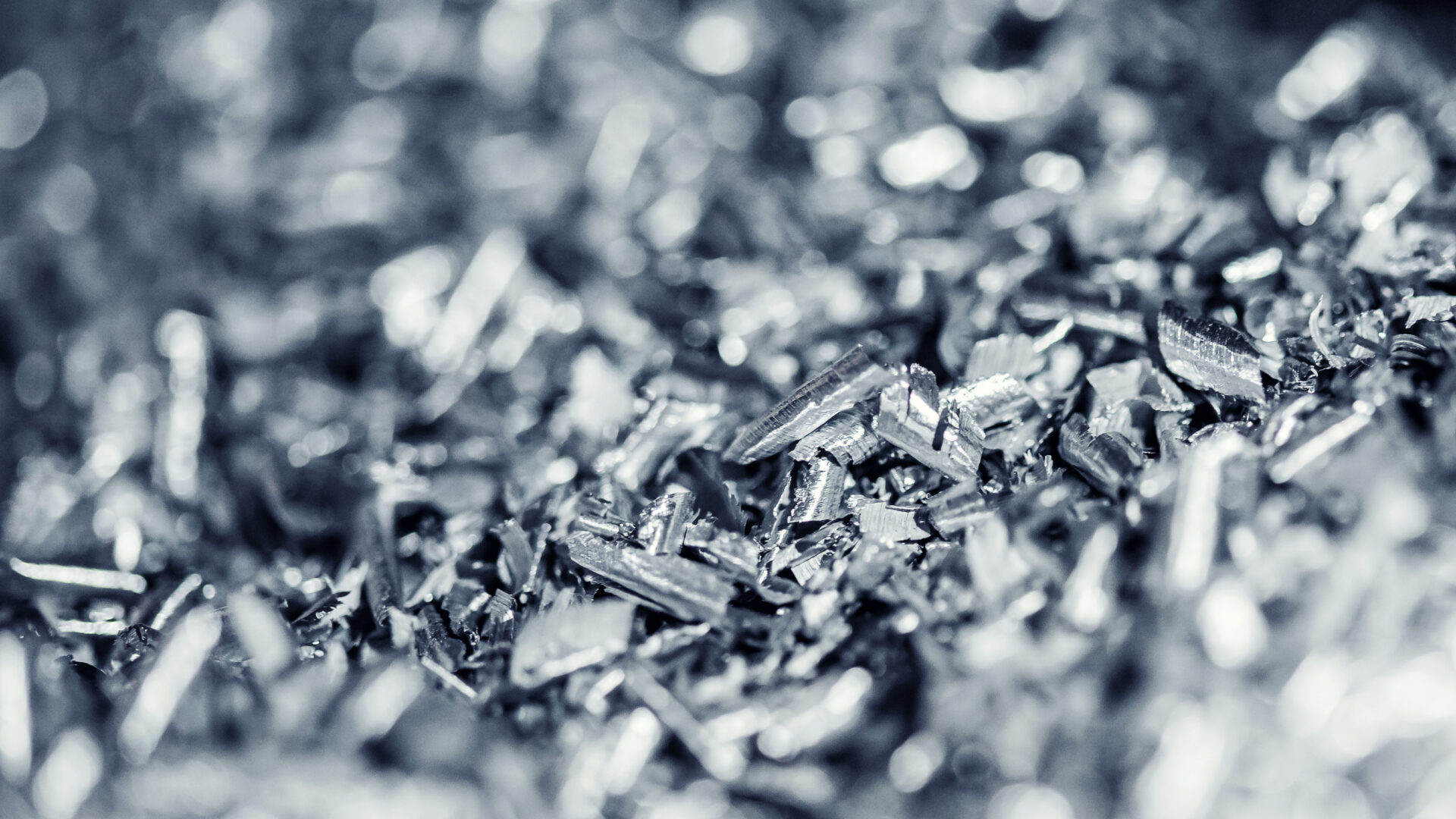

Chip Management

Proper swarf handling is essential to minimize fire risk. Chips must be kept dry, segregated, and stored in non-combustible containers. Fine swarf should be avoided due to flammability. Recycling is feasible, especially with dry chips.

Fire Safety

While solid magnesium is not highly flammable, fine chips can ignite. Suitable extinguishers (e.g. Met-L-X) should be on hand. Water, CO₂, and nitrogen must not be used.

Applications

Standard machining operations (turning, milling, drilling, tapping) are feasible with modifications. Careful control of parameters ensures safety, dimensional accuracy, and tool life.

Design with Magnesium

For information on how to design with magnesium, register for a copy of our design guide.

Products

Make an enquiry

Please fill in this form to contact us for sales, support or general enquiries. Thank you.