US +1 908 782 5800 | UK & Rest of World +44 (0) 330 822 6000

Elektron® WE43B

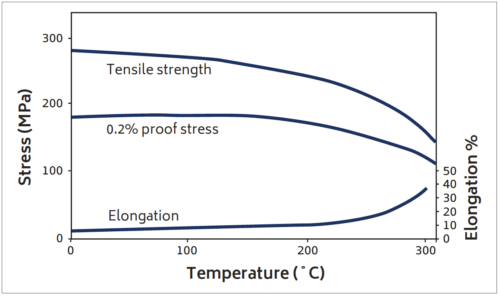

A high strength magnesium based casting alloy developed by Luxfer MEL Technologies for use at temperatures up to 300˚C.

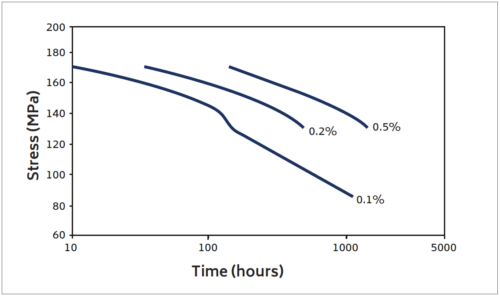

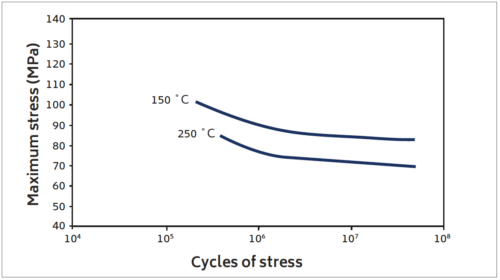

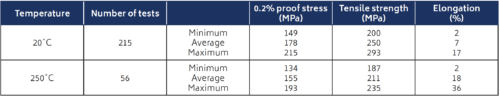

This alloy maintains its mechanical properties at elevated temperatures, without the use of either silver or thorium. The alloy is stable for long term exposure up to 250˚C. Elektron® WE43B also has excellent corrosion resistance characteristics.

Product Information

Find out more about this product below.

Support and downloads

Make an enquiry

Please fill in this form to contact us for sales, support or general enquiries. Thank you.