US +1 908 782 5800 | UK & Rest of World +44 (0) 330 822 6000

Luxfer MEL Technologies Lightweight Magnesium Alloys

Luxfer MEL Technologies has created a unique range of lightweight extruded magnesium alloys that offer numerous advantages over conventional materials.

Low Density and High Strength-to-Weight Ratio

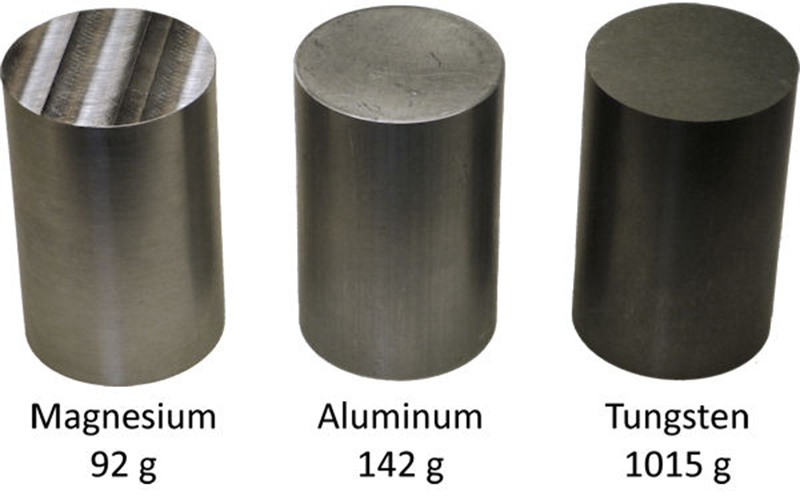

Magnesium alloys have a key property that sets them apart from other metals: their low density. With a density of just 1.74 g/cm3, magnesium alloys are significantly lighter than aluminum (2.7 g/cm3) and steel (7.8 g/cm3). This lightweight characteristic makes them a popular choice for applications where weight reduction is essential, such as in aerospace and automotive industries.

Another notable property of magnesium alloys is their high strength-to-weight ratio. These alloys can achieve tensile strengths comparable to other structural metals like aluminum and steel, while maintaining a much lower weight. This balance of strength and weight reduction makes magnesium alloys an ideal choice for applications that demand both qualities.

Machinability, Castability, and Corrosion Resistance

Magnesium alloys are known for their excellent machinability, allowing them to be easily cast, forged, and extruded. They can be welded and brazed without difficulty, and exhibit good corrosion resistance. Additionally, magnesium alloys possess remarkable damping properties, making them valuable for applications requiring vibration isolation and noise reduction.

Luxfer’s Elektron® 43 Alloy: A Game-Changer in Magnesium Applications

Luxfer MEL Technologies has developed a range of unique magnesium alloys that further enhance the benefits of magnesium materials. The Elektron® 43 alloy is a lightweight, high-strength wrought magnesium alloy designed for use at temperatures up to 250˚C. Designs incorporating Elektron® 43 can achieve a 20% to 30% weight reduction compared to a corresponding aluminum design.

Elektron® 43 is available in various forms, including rolled plate, forging feedstock, and extruded bar, section, and profile. This alloy represents an optimised wrought evolution of the original casting alloy, Elektron® WE43.

The properties of Elektron® 43 make it well-suited for use as feedstock material for machining high-performance components, particularly those associated with elevated temperature performance.

Conclusion

Magnesium alloys, with their low density and high strength-to-weight ratio, are a fascinating class of materials suitable for a wide range of applications, including aerospace, automotive, and electronics. Luxfer MEL Technologies’ Elektron® 43 alloy is a testament to the potential of magnesium alloys in revolutionising various industries.