Resins and Zirconium, where do we stand?

Zirconium’s role in resin formulations

Different types of resins play a role in our everyday life, whether it is using an epoxy resin to fix a crack in your windscreen or a polypropylene resin molded into a bottle to hold your cleaning chemicals.

In this post, we are going to look at the function of resins and how adding zirconium into the resin formulation can improve certain properties that can be beneficial in industries such as the coatings industry. Lastly, we will look at the future of bio-based resins.

Resin process in the coatings industry

Traditional resins such as alkyd or epoxy are fully dispersed in the coating formulation, meaning the resin has spread throughout the coating once it has been applied.

However, as heat is used to dry the coating the resin moves to the surface where it crosslinks with itself to form a hydrophobic film on the surface of the coating. In industries where they want water repellent properties this is viable, but in the coatings industry this can lead to printing problems such as ink refusal and poor adhesion.

Adding zirconium to the formulation, why does it matter?

Zirconium species do not move towards the surface as heat is applied, zirconium stays within the body of the coating and crosslinks with binder molecules close by. As zirconium has cross-linked throughout the body of the coating, no hydrophobic film has formed meaning there is less chance of ink refusal problems and improved ink adhesion.

Additionally, oxygen can pass through the coating to improve the cure time. For more information check out our staple product Bacote 20.

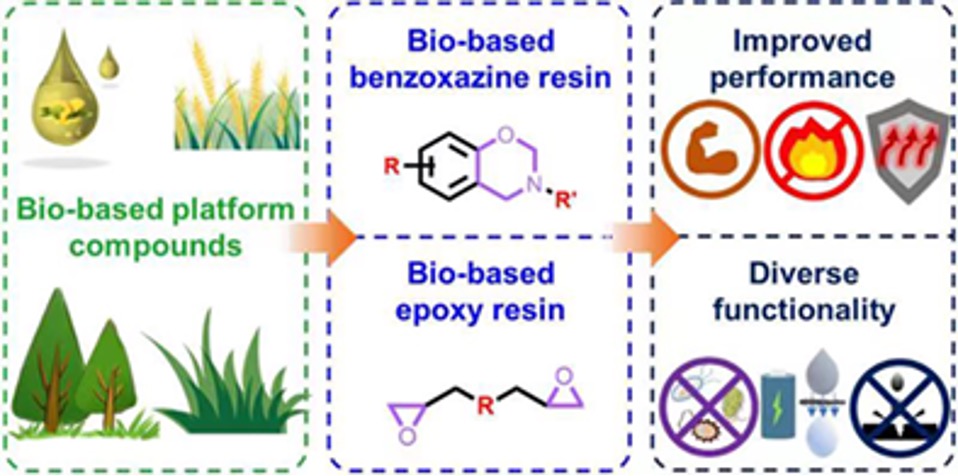

The future: Bio based resins

As a result of global warming and the environmental push towards sustainable systems and greener products, bio-based resins offer the greatest potential for replacing/reducing paints and coatings based on fossil raw materials.

New resins vary in bio content, ranging from 30-100%. The most common plant sources for the production of bio resins are corn and soybean by-products from bio-diesel refinement. It is known that zirconium species may function the same way however further research is needed.

In conclusion, as we move towards greener resins, zirconium still offers unique properties as a cross linker in the coating formulation.