US +1 908 782 5800 | UK & Rest of World +44 (0) 330 822 6000

An accomplished solution to downhole problems with a High Ductile Alloy

In the realm of oil and gas industry innovations, SoluMag® HD has emerged as an exceptional product within the SoluMag® platform. Designed to address specific challenges in downhole applications, SoluMag® HD is a magnesium alloy known for its high ductility and controlled corrosion in aqueous chloride environments. This blog post will delve into the unique properties and applications of SoluMag® HD seamless tubes, shedding light on how they offer a cutting-edge solution for dissolvable frac plug components.

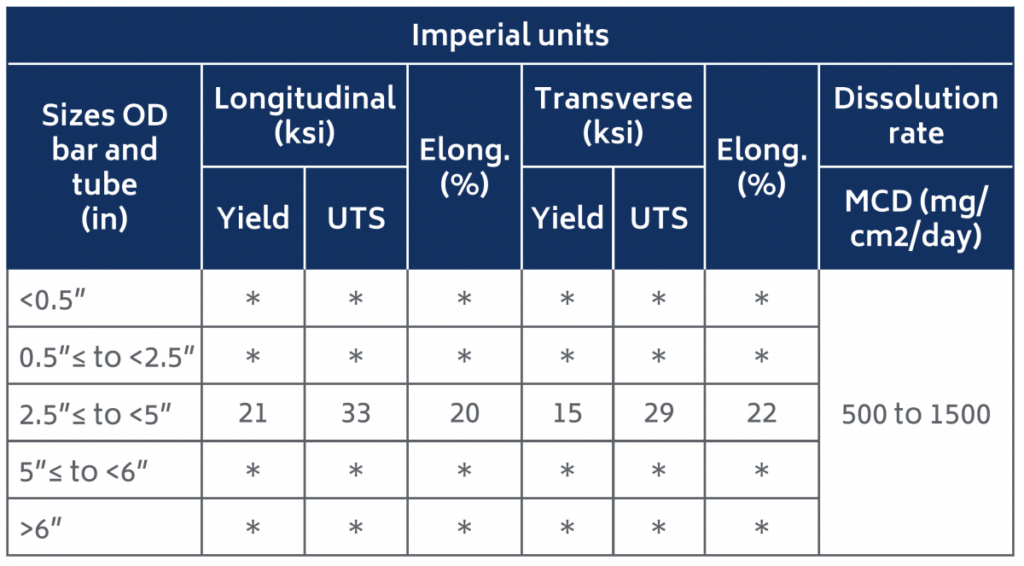

Mechanical properties

* Contact Luxfer representative for additional information

+ Transverse data not available

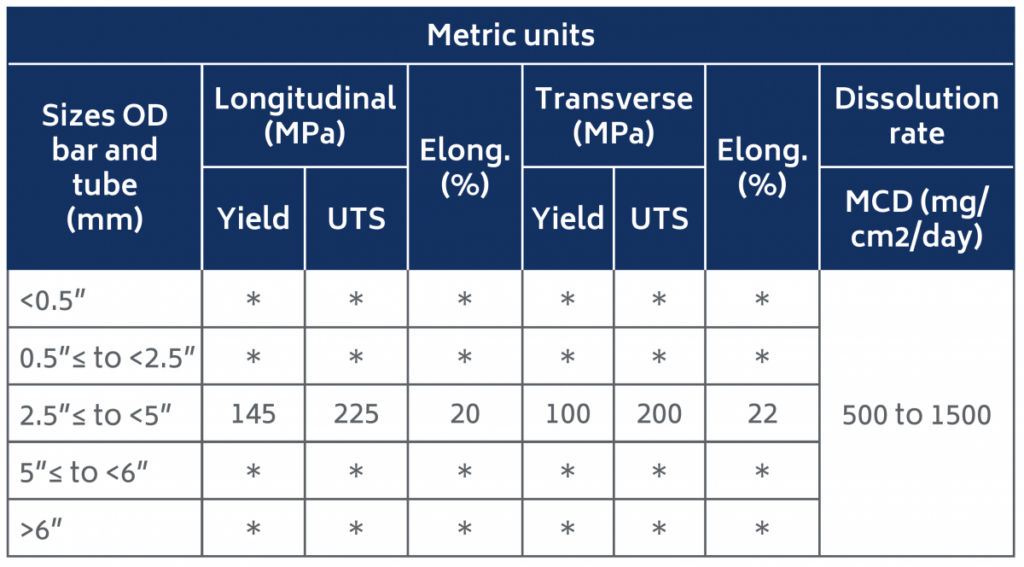

* Contact Luxfer representative for additional information

+ Transverse data not available

Unveiling the SoluMag® HD Alloy

SoluMag® HD is an advanced magnesium alloy that stands out for its exceptional ductility. Unlike conventional dissolvable magnesium alloys, SoluMag® HD boasts an elongation rate exceeding 22% while maintaining its mechanical strength properties. This means that SoluMag® HD can undergo significant deformation without compromising its structural integrity, making it an excellent choice for demanding downhole environments.

Versatile Forms for Various Applications

To cater to diverse operational requirements, SoluMag® HD is available in multiple forms, including extruded tubes, rods, and bars. These seamless tubes are noteworthy for their exceptional performance in downhole applications. The high ductility of SoluMag® HD seamless tubes makes them a valuable asset in dissolvable frac plug components that require substantial expansion post-set.

Superior Ductility and Controlled Corrosion

SoluMag® HD seamless tubes offer a solution to downhole challenges by combining superior ductility with a well-controlled corrosion rate. The alloy’s high ductility allows it to expand significantly after setting, which is crucial for dissolvable frac plug components.

Lightweight Construction

SoluMag® HD seamless tubes are lightweight, making them an ideal choice for applications that prioritize weight reduction. The reduced weight contributes to overall operational efficiency and cost-effectiveness.

Increased Performance

The exceptional ductility of SoluMag® HD seamless tubes enables dissolvable frac plug components to expand effectively, providing optimal sealing and performance in downhole operations.

Conclusion

SoluMag® HD seamless tubes offer a ground-breaking solution to downhole challenges. Their high ductility, and controlled corrosion rate make them an ideal choice for dissolvable frac plug components that require substantial expansion post-set.

With the benefits of lightweight construction, enhanced durability, and increased performance, SoluMag® HD seamless tubes stand at the forefront of innovation, facilitating more efficient and reliable operations in the oil and gas sector. Want to find out more? Contact the team below.