US +1 908 782 5800 | UK & Rest of World +44 (0) 330 822 6000

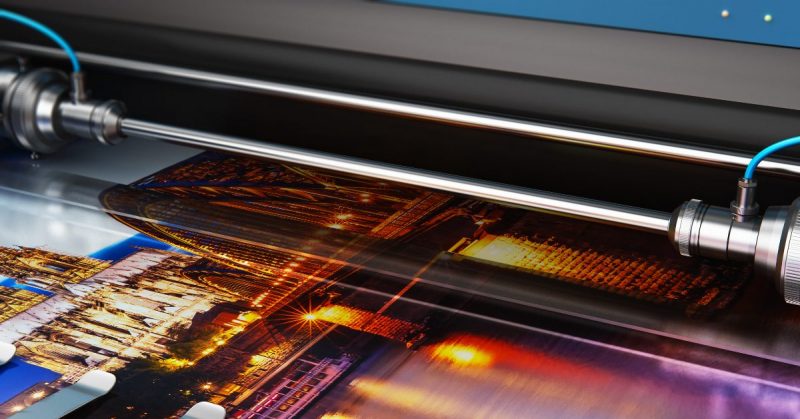

Providing Adhesion Solutions to the Printing Industry

In the evolving printing industry, the drive for innovation is met with unique challenges, particularly in ink formulation and substrate compatibility. As the demand for high-quality, durable printed materials grows, especially within the food packaging sector, the need for effective adhesion promoters and paint additives has never been more critical.

These solutions address common issues such as weak adhesion, inadequate heat and scrub resistance, ensuring products withstand environmental stresses and maintain their visual appeal.

The Criticality of Strong Adhesion in Printing Inks:

Weak adhesion compromises the physical appearance and durability of printed materials, leading to products that fail to meet industry standards and consumer expectations. In food packaging, where visual appeal directly influences consumer choices, ensuring optimal adhesion is paramount.

Employing advanced adhesion promoters can significantly enhance the bond between ink and substrate, resulting in a superior end product.

Overcoming Environmental Challenges – Scrub and Heat Resistance:

Environmental resilience in printed materials is essential for maintaining integrity from production through to end consumer handling. Enhancements in scrub resistance ensure that products remain visually appealing and informationally accurate, despite everyday wear and tear.

Similarly, improved heat resistance is crucial for products exposed to varying temperatures, protecting against degradation and ensuring longevity.

Zirconia Based Solutions by Luxfer MEL Technologies

Bacote® 20

Bacote 20® stands at the forefront of addressing adhesion and durability challenges in water-based ink systems. By facilitating the crosslinking of pigments onto substrates, it significantly enhances adhesion and scrub resistance, making it an invaluable asset for the food packaging industry.

Zirconium Propionate

Zirconium Propionate emerges as a game-changer for solvent-based inks, including flexographic and gravure inks. Its ability to improve ink adhesion on challenging substrates like polypropylene opens new avenues for printing on a variety of materials, achieving desired aesthetic outcomes with high efficiency.

Luxfer MEL Technologies offers a wide range of coatings and solutions products for the ink and paperboard industries applications.